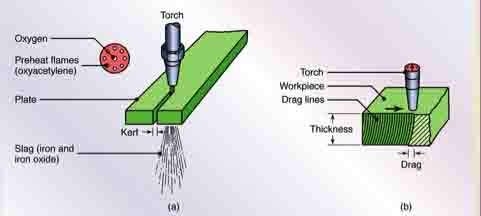

Oxy acetylene fuel cutting occurs when oxygen is directed to heated metal resulting in the metal burning or oxidizing away.

Oxygen is required to support any burning process. Oxygen is not flammable by itself, however, it increases the speed and force with which burning takes place.

When combined with acetylene, the flame becomes hotter and combustion is faster.

An oxyfuel torch can be fitted with cutting attachments instead of using a welding head.

The cutting attachments can be used to cut steel approximately 6 inches thick.

Oxyfuel cutting operations can use gasses such as oxygen, acetylene, MAPP, natural gas and propane.

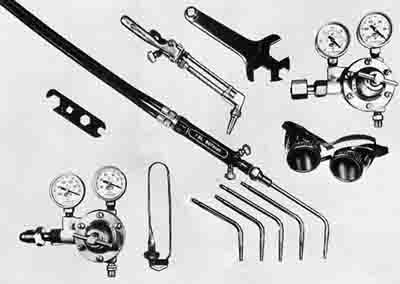

Oxyacetylene Equipment Check List Includes:

- Oxygen regulator

- Acetylene regulator

- Oxygen/Acetylene welding hose

- Hose couplings

- Single-purpose oxyfuel cutting torch

- Cylinders and cart

- Flash arrestor and check vales (protective equipment)

- Flint lighter to ignite torch

Oxy Acetylene Cutting Torch

Oxy Acetylene Torch Styles

The cutting torch (see figure 5-12 below), like the welding torch, has a tube for oxygen and one for acetylene. In addition, there is a tube for high pressure oxygen, along with a cutting tip or nozzle.

Tip: The tip (see figure 5-13) is provided with a center hole through which a jet of pure oxygen passes. Mixed oxygen and acetylene gas pass-through holes surrounding the center holes for the preheating flames. The number of orifices for oxy-acetylene flames ranges from 2 to 6, depending on the purpose for which the tip is used.

Related: Oxy-Acetylene Cutting Torch Kits – Top Picks

Oxyacetylene Cutting Tip Diagram

Torch Control: The cutting torch is controlled by a trigger or lever operated valve. The cutting torch is furnished with interchangeable tips for cutting steel from less than 1/4 in. (6.4 mm) to more than 12.0 in. (304.8 mm) in thickness.

A cutting attachment fitted to a welding torch in place of the welding tip is shown in figure 5-14.

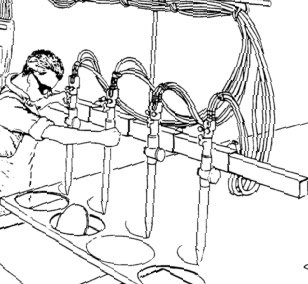

In order to make uniformly clean cuts on steel plate, motor-driven cutting machines are used to support and guide the cutting torch.

Straight-line cutting or beveling is accomplished by guiding the machine along a straight line on steel tracks.

Arcs and circles are cut by guiding the machine with a radius rod pivoted about a central point.

Typical cutting machines in operation are shown in figure 5-15 and figure 5-16.

Oxyfuel Cutting Tip Styles

There is a wide variety of cutting tip styles and sizes available to suit various types of work. The thickness of the material to be cut generally governs the selection of the tip. The cutting oxygen pressure, cutting speed, and preheating intensity should be controlled to produce narrow, parallel-sided kerfs.

Cuts that are improperly made will produce ragged, irregular edges with adhering slag at the bottom of the plates. Table 5-3 identifies cutting tip numbers, gas pressures, and hand-cutting speeds used for cutting mild steel up to 12 in. (304.8 mm) thick.

Oxyacetylene Cutting Information – Table 5-3

Operation of Oxy acetylene Cutting Equipment

Flame Cutting Steel Plate

Oxygen Acetylene Welding Cutting Torch Video

Oxyfuel Operating Steps:

Here are the operating steps for oxyfuel cutting:

- a. Attach the required cutting tip to the torch and adjust the oxygen and acetylene pressures in accordance with table 5-3 above.

NOTE The oxygen and acetylene gas pressure settings listed are only approximate. In actual use, pressures should be set to effect the best metal cut. - Adjust the preheating flame to neutral.

- Hold the torch so that the cutting oxygen lever or trigger can be operated with one hand. Use the other hand to steady and maintain the position of the torch head to the work. Keep the flame at a 90 degree angle to work in the direction of travel. The inner cones of the preheating flames should be about 1/16 in. (1.6 mm) above the end of the line to be cut. Hold this position until the spot has been raised to a bright red heat, and then slowly open the cutting oxygen valve.

- If the cut has been started properly, a shower of sparks will fall from the opposite side of the work. Move the torch at a speed which will allow the cut to continue penetrating the work. A good cut will be clean and narrow.

- When cutting billets, round bars, or heavy sections, time and gas are saved if a burr is raised with a chisel at the point where the cut is to start. This small portion will heat quickly and cutting will start immediately. A welding rod can be used to start a cut on heavy sections. When used, it is called a starting rod.

Oxyacetylene Cutting Hose

Safety Practices

General requirements include (follow manufacturers directions):

- Always check for tight hose connections and leaks

- Blow out the cylinder value

- Do not stand behind or in front of regulator when opening the cylinder value

- First turn on cylinder value and then adjust the regulator pressure screw

- Slowly open the cylinder valve

- Purge any oxygen and acetylene passages

- Make sure mixing know is off before lighting torch

- Light the acetylene

- Never use with grease or oil. Do not handle with greasy gloves or oily hands. Oil and grease can become explosive in hte presence of oxygen!

- Do not substitute oxygen for air

- Keep the work area clean

- Note that oxyacetylene becomes unstable above 15 PSI, do not use above this level (oxygen max is 40 psi)

- Do not pick up materials with gloves after cutting