Understanding welding metals is one of the pillars of knowledge needed to be a successful welder.

Each metal and metal alloy responds differently to heat and in the way they can be manipulated.

Metals expand and soften when heated, resulting in different uses and applications.

They also respond in different ways to the various types of welding methods used.

Review the characteristics of each of metal below.

Considerations

There are several considerations when selecting a metal for welding. This includes:

- Melting point

- Ductility: how the metal reacts to bending, stretching

- Electrical Conductivity: effects what the metal can be used for

- Strength: what is the breaking point of a metal

Types of Welding Metals

Steel

Everyone is familiar with the strength of steel.

It is an alloy that contains iron and 2% of other elements.

Carbon/steel alloy is common and can be found in high, low and medium varieties.

Higher carbon content means stronger steel.

Steel is versatile and can be used with any welding process. Welding areas need to be cleaned.

On the downside, it can rust and flake from oxidation.

Stainless Steel

Unlike plain steel, stainless is made to resist corrosion and is hygienic.

This is achieved by adding 10% to 30% chromium to other elements such as iron. There is also a nickel alloy available.

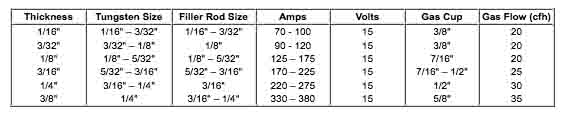

Stainless is welded using arc welding (TIG, MIG or Stick).

The downside is the higher cost.

Related read: How to Weld Stainless Steel

Aluminum

Like stainless steel, aluminum isn’t as corrosive as other metals.

It is lighter than stainless steel. In welding, pure aluminum and alloys are used.

Alloys include:

- copper/aluminum alloy

- manganese alloy

- zinc alloy

When it comes to welding aluminum, there are a few choices.

GTAW welding (TIG) aluminum is the preferred arc welding method as it produces the best results.

You can also GMAW (MIG) weld aluminum and get good results.

Stick aluminum welding is only used for smaller projects.

The process starts by selecting a joint design for the base metals (tee, lap, edge, corner or butt).

Related: How Do You Weld Aluminum To Steel?

Copper

Among the welding metals, copper is popular due to its electrical conductivity, heat conductivity, corrosion resistance, appearance and wear resistance.

To be called copper it needs to be 99.3% minimum copper content.

Processes used in welding include welding, brazing and soldering. There are multiple types of copper alloys:

- copper-nickel-zinc (called nickel silver)

- copper-nickel

- copper-silicon (called silicon bronze)

- copper-aluminum alloy (aluminum bronze)

- copper-tin

- copper-zinc (also known as brass)

- high copper alloys (up to 5% alloy)

Copper is welded using Gas Tungsten Arc Welding (TIG) and Gas Metal Arc Welding.

Some welders will use manual metal arc welding, but it can result in poor quality.

When welding copper the joint designs are wider than those recommended for steel. The shielding gas for copper is welding grade argon.

Weld areas are cleaned with a wire bronze brush and then degreased. Oxides that form should be removed after welding.

Copper is preheated, however, copper alloys do not need to be preheated due to high levels of thermal conductivity.

Cast Iron

In terms of welding metals, low carbon steel is easier to weld than cast iron.

Cast iron has higher carbon and silicon content, and is not as ductile.

When welding with cast iron the surface will need to be cleaned to remove any ingrained grease and oil. All cracks need to be grinded or filed.

Cast iron is welded with oxyacetylene welding.

Nickel Alloys

Nickel welding metals come in the form of several alloys. These include:

- Nickel Alloy 141: Used for welding case and wrought pure nickel (nickel 200 and 201). It is also used to join nickel to steel.

- Nickel Alloy 61: Same as above.

- Nickel-Copper Alloy 190: For welding to itself or to stell.

- Nickel-Copper Alloy 60: Used for welding to itself.

Magnesium

Magnesium alloys are lightweight (2/3 of aluminum), it absorbs vibration and is easy to cast. It has a melting temperature similar to aluminum and is welded in a similar way.

When you grind magnesium note that the shavings are flammable (do not use water to put out any flames). The metal is welded with a Tig welder.

For Additional Reading